What is an Industrial Panel PC and How Does It Work

In the rapidly evolving landscape of industrial automation, the role of the industrial panel PC has become increasingly vital. Defined as a robust computing solution designed specifically for industrial environments, industrial panel PCs integrate the functionalities of traditional PCs with rugged hardware to withstand extreme conditions. According to a recent report by MarketsandMarkets, the global industrial PC market is projected to reach USD 4.5 billion by 2026, growing at a CAGR of 6.5% from 2021. This growth is driven by the surge in demand for real-time data processing and machine-to-machine communication in manufacturing and industrial settings. As industries prioritize efficiency and automation, understanding how industrial panel PCs work is essential for leveraging their capabilities to enhance productivity and reliability in critical operations.

Understanding the Basics of Industrial Panel PCs and Their Components

Industrial Panel PCs

are robust computing devices designed specifically for demanding environments typically found in manufacturing, process control, and automation sectors. These systems combine a display unit and computer into a single device, often featuring touchscreens for intuitive user interaction. According to a recent report by MarketsandMarkets, the Industrial PC market is expected to grow from USD 4.8 billion in 2021 to USD 8.8 billion by 2026, underscoring the increasing demand for these versatile solutions.

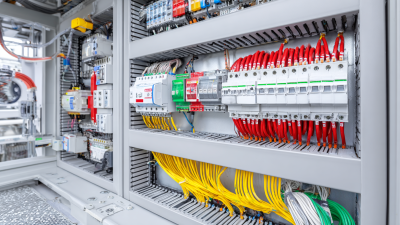

The key components of an Industrial Panel PC include the processor, memory, storage, and input/output interfaces, all housed within a sturdy enclosure that can withstand harsh conditions such as dust, moisture, and extreme temperatures. Many models utilize fanless designs and solid-state drives to ensure reliability and longevity. A study by IDC indicates that the adoption of these systems can enhance operational efficiency by up to 30%, allowing manufacturers to streamline their processes and reduce downtime. With advancements in technology, such as IoT integration and improved graphics capabilities, Industrial Panel PCs are becoming essential for modern industrial applications.

Key Features of Industrial Panel PCs for Various Applications

Industrial Panel PCs are essential components in various applications ranging from manufacturing to transportation, equipped with features that enhance their versatility and performance. For example, the recent integration of a 28.5-inch HiRaso panel PC into concept trains demonstrates the push towards incorporating advanced display technologies in vehicle systems. This innovative display technology is based on cholesteric liquid crystals, which offer energy efficiency and superior visibility in challenging environments, aligning with the demands of modern industrial applications.

Industrial Panel PCs are essential components in various applications ranging from manufacturing to transportation, equipped with features that enhance their versatility and performance. For example, the recent integration of a 28.5-inch HiRaso panel PC into concept trains demonstrates the push towards incorporating advanced display technologies in vehicle systems. This innovative display technology is based on cholesteric liquid crystals, which offer energy efficiency and superior visibility in challenging environments, aligning with the demands of modern industrial applications.

Moreover, the emergence of modular panel PCs has revolutionized the industrial computing landscape, offering over 30 customizable design choices. This flexibility allows manufacturers to tailor their solutions to specific operational needs, ranging from machine-level control to monitoring systems. According to industry reports, global shipments of industrial display panels reached 281.1 million units, underscoring the growing reliance on these technologies across sectors. As industries continue to embrace digital transformation through Industry 4.0 technologies, the functionality and adaptability of Industrial Panel PCs will play a crucial role in driving efficiency and innovation in various applications.

How Industrial Panel PCs Operate: Hardware and Software Integration

Industrial Panel PCs integrate hardware and software to deliver efficient solutions for various industrial applications. At the heart of these systems, the hardware typically consists of a ruggedized touchscreen, a reliable processor, and extensive I/O connectivity options tailored for tough environments. According to a report from MarketsandMarkets, the global industrial PC market is expected to grow from $3.5 billion in 2020 to $5.6 billion by 2025, indicating the rising reliance on such technologies in manufacturing and automation sectors.

The software component of Industrial Panel PCs is equally critical, as it enables communication with machinery and data processing. They often run on robust operating systems like Windows or Linux, providing compatibility with various industrial software solutions, such as SCADA systems and HMI applications. Effective integration between hardware and software ensures real-time monitoring and control, which is vital for optimizing productivity and minimizing downtime. A study by Research and Markets highlights that the adoption of smart factory solutions, where Panel PCs play a crucial role, is projected to surpass $500 billion by 2025.

Tips: When selecting an Industrial Panel PC, consider the specific environmental conditions it will operate in, such as temperature fluctuations and dust exposure. Opt for models with IP-rated enclosures for optimal protection. Additionally, ensure that the panel is compatible with your existing software ecosystem to enhance operational efficiency.

Comparing Industrial Panel PCs with Traditional Computing Solutions

Industrial Panel PCs are specialized computing solutions designed for use in manufacturing and industrial environments, where durability and functionality are critical. Unlike traditional desktops or laptops, which often have limitations in terms of environmental resilience, Industrial Panel PCs are built to withstand harsh conditions such as extreme temperatures, dust, and moisture. This robust construction allows them to operate reliably in demanding settings like factories, warehouses, and control rooms.

When compared to traditional computing solutions, Industrial Panel PCs offer several advantages. They typically feature integrated touchscreens, which streamline user interactions and reduce the need for additional input devices. Their compact design and all-in-one construction save space and simplify installation processes. Furthermore, many Industrial Panel PCs are equipped with more powerful processing capabilities and can support industrial-specific applications, enhancing functionality and efficiency in operations. In contrast, traditional computing solutions may require additional hardware and are often less capable of enduring the rigors of industrial environments. This makes Industrial Panel PCs a preferred choice for industries that demand both performance and reliability.

Benefits of Utilizing Industrial Panel PCs in Modern Manufacturing Environments

Industrial Panel PCs have become integral to modern manufacturing environments, offering numerous benefits that enhance efficiency and productivity. According to a report by Research and Markets, the global industrial PC market is projected to reach $5.07 billion by 2024, driven by the increasing demand for automation in manufacturing processes. These devices combine the durability of industrial controls with the functionality of personal computers, making them ideal for environments that require both resilience and advanced computing.

One of the key advantages of utilizing Industrial Panel PCs is their ability to streamline operations. By integrating touch-screen interfaces with real-time data processing, these systems allow operators to monitor and control machinery directly from the production floor. A study from MarketsandMarkets suggests that automation in the manufacturing sector can lead to efficiency improvements of up to 30%. Additionally, Panel PCs reduce the amount of space required for separate screens and controls, promoting a more organized and efficient work environment. As manufacturers continue to embrace Industry 4.0 principles, the relevance of Industrial Panel PCs in supporting interconnected processes is more critical than ever.

Usage of Industrial Panel PCs in Manufacturing Environments

Related Posts

-

5 Essential Tips for Choosing the Right Industrial Panel PC for Your Business

-

How to Optimize Your Industrial Computing Products for Maximum Efficiency

-

10 Essential Tips for Choosing the Right Industrial Computer System for Your Business

-

The Definitive Guide to Rugged Touch Panel PCs Enhancing Industrial Operations and Productivity

-

How to Choose the Right Rugged PC for Your Industrial Needs

-

How to Optimize Industrial Panel Efficiency: Insights from the Latest Market Trends and Data